Maximizing Effectiveness: The Importance of Genuine Komatsu Undercarriage Parts

Maximizing Effectiveness: The Importance of Genuine Komatsu Undercarriage Parts

Blog Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

When it involves heavy equipment, the undercarriage is a critical component that usually determines the total efficiency and efficiency of the devices. Quality undercarriage components play a considerable role in making certain the smooth operation and long life of heavy equipment. From excavators to dozers, each piece of equipment relies heavily on its undercarriage to withstand hard working problems. Wear and tear are unpreventable, leading to potential problems that can impede performance and increase upkeep prices. In this discussion, we will discover the significance of investing in first-class undercarriage parts, usual wear challenges encountered by hefty machinery drivers, the benefits of prompt substitutes, guidelines for picking dependable providers, and crucial upkeep tips to extend the life-span of undercarriage components.

Relevance of Quality Undercarriage Components

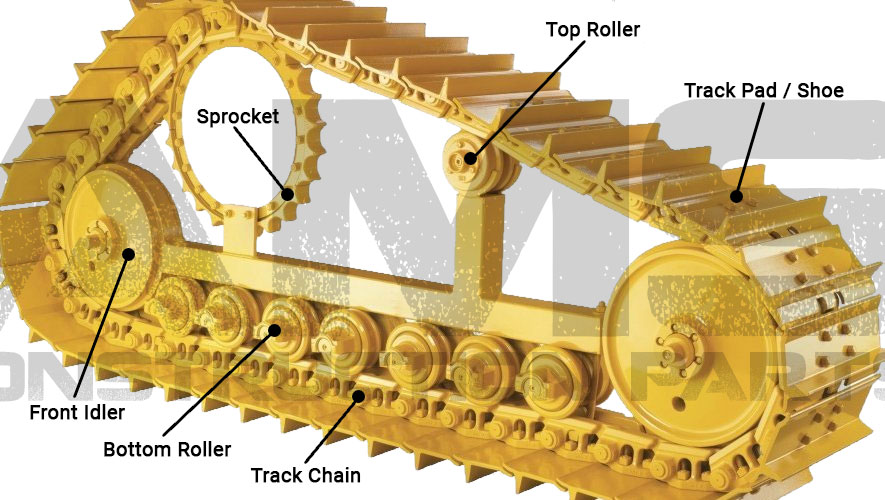

Quality undercarriage components are vital elements in making certain the durability and efficiency of heavy equipment. The undercarriage of tools such as excavators, bulldozers, and track loaders plays a crucial duty in sustaining the machine's weight, giving security on different surfaces, and absorbing the effect of irregular surfaces. By buying high-grade undercarriage parts, drivers can substantially prolong the life-span of their machinery and minimize the danger of unexpected failures.

One secret advantage of using top quality undercarriage components is the improvement of total device performance. Resilient tracks, rollers, idlers, and gears lower friction and guarantee smoother motion, ultimately causing raised performance and efficiency on job websites. In addition, reputable undercarriage components reduce downtime for upkeep and repair services, allowing operators to optimize their functional hours and project target dates.

Common Undercarriage Use Problems

Advantages of Timely Substitute

One secret advantage of timely undercarriage part substitute is increased machine uptime. By replacing used parts before they fail, the threat of unanticipated failures is reduced, lowering downtime for fixings and upkeep. This aggressive technique not just keeps the heavy equipment functional however also prevents possible damage to other elements that can arise from a stopping working undercarriage.

Furthermore, changing undercarriage components without delay can improve overall performance. A well-kept undercarriage ensures optimum device efficiency, permitting smoother procedure and higher effectiveness in completing jobs. This, subsequently, causes raised task site performance and expense financial savings by avoiding disruptions and delays triggered by underperforming machinery. Investing in timely undercarriage part substitute is a positive technique that pays off in terms of enhanced effectiveness and lowered functional prices.

Selecting the Right Undercarriage Supplier

Picking the ideal undercarriage vendor is a critical choice that considerably influences the performance and upkeep of heavy machinery. When selecting a vendor for undercarriage components, several factors have to be considered to guarantee optimum performance and cost-effectiveness. A provider that uses a large selection of undercarriage parts for numerous heavy machinery brand names and models can be helpful as it offers extra options to satisfy certain requirements.

Stabilizing integrity, high quality, and cost-effectiveness is vital when choosing the right undercarriage provider for heavy machinery. By thoroughly reviewing these factors, you can choose a distributor that fulfills your needs and adds to the efficient performance and upkeep of your heavy machinery.

Maintenance Tips for Extended Life-span

To make sure a prolonged life-span for heavy equipment undercarriage parts, implementing a proactive maintenance regimen is crucial. Regularly inspecting undercarriage parts such article as track chains, idlers, rollers, and sprockets for wear and tear is critical. look at this site Any indications of damages or too much wear need to be without delay dealt with to stop additional damage and prospective failings. In addition, keeping the undercarriage clean from dust, particles, and destructive products can dramatically prolong its life expectancy. Greasing moving components according to maker recommendations aids lower rubbing and avoid early wear. Keeping track of track tension and alignment is also crucial to stop irregular wear on the undercarriage parts. Purchasing high quality undercarriage parts from trusted vendors is equally essential for ensuring long life. By adhering to these upkeep tips diligently, heavy machinery owners can enhance the efficiency and durability of their undercarriage parts, ultimately reducing downtime and functional prices.

Final Thought

In final thought, quality undercarriage parts are necessary for the reliable procedure of hefty equipment. Picking a trusted supplier and following appropriate upkeep methods are vital to ensuring the extended life-span of undercarriage parts.

Too much wear and tear on undercarriage parts of heavy equipment can lead to substantial operational obstacles and enhanced maintenance prices. Normal inspections, correct upkeep, and timely substitutes of used undercarriage parts are necessary to alleviate these common wear Resources issues and make certain the optimal functioning of heavy machinery.

A vendor that uses a broad option of undercarriage components for various heavy equipment brands and designs can be beneficial as it offers a lot more alternatives to satisfy details needs.

By adhering to these maintenance pointers faithfully, heavy equipment owners can maximize the efficiency and durability of their undercarriage components, inevitably reducing downtime and functional prices.

Report this page